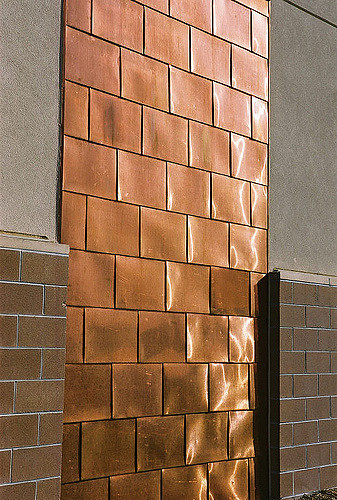

Copper cladding is a very popular construction material in the UK. Why?

Well we ate Grey’s of London have been thinking a lot about this question, and here are the answers!

Copper is a light weight, durable, abrasion resistant 100% recyclable and beautiful material. It is easily manipulated and will not cause an obscene amount of aggravation during installation. It is also very light and this means that moving it from A to B will not be a problem for you or anyone else who chooses copper as their clad.

Copper is a beautiful material that brightens up any scenario. The sheer shine and light reflection of the copper is good for somewhere that has a tendency to be dark as it will bring light, but also for somewhere that receives an immense amount of sunshine as it will glow!

Copper is a very expensive material and that needs to be considered when looking to use it for your cladding. It will require a lot of love and care in the beginning, and it may become dull and dank looking if not treated correctly during the installation and initial treatment.

When considering how you want to install your copper, you need to look at all of the options available, in the UK and most of Europe, there are 4 main options to consider:

- Seamed cladding

- Shingle cladding

- Slot in panels

- Cassettes

The most popular among these options is slot in panels, it comes in large sheets of copper that are then cut to size and slotted into the correct place. This is the easiest and most seamless option for anyone wishing to use copper cladding. The copper is so malleable that cutting it to size is very easy!

The only problem that you may experience with this copper cladding is that due to how easily manipulated it is, the dents that can occur during installation are very likely. In order to prevent such an occurrence, it should be fitted by professionals that are aware of the risks involved and how to overcome them.

Once the installation technique has been selected, the next thing to consider is how to protect the copper. There are a variety of options that are up for consideration. But when the options are laid out, it needs to be noted that almost 50% of the treatments and protective materials available are only for use on interior applications.

The best treatments and protective materials available are:

- Acrylic coating – This can be used for air drying or thermosetting compositions. The air drying composition is the most viable option for exterior structures but it must be thought through carefully due to its high cost.

- Silicone coating – This is the best potential for coatings which must operate at elevated temperatures, So if you are living in a relatively warm climate it is necessary to look into this type of coating as it is the most effective for that type of scenario. Thin films are used and put onto the copper (Very high cost). After this has set onto the copper, a second coat of a more durable abrasion resistant lacquer may be necessary. Not only will this increase the longevity of the copper’s life, but it will ensure that it looks shiny and new for years and years to come. There will be no need to go back to the drawing board less than a year later and consider another option in order to either remove tarnishing, or completely start from scratch. UV absorbers need to be added to this treatment to prevent darkening of the silicone.

- Alkyd coating – slow drying or baking is required when applying alkyd coatings. It is modified with melamine resins in order to use the sunlight to its advantage. This coating is very low cost and very very VERY effective on exterior structures due to its resourcefulness of natural sunlight, it also exudes it’s ability to resist chemicals, meaning that years of heavy rainfall are not going to diminish it’s overall appearance.

- The overall winner of protective copper coatings however is the polyvinyl fluoride film (tediars) – It is applied by roll bonding with an adhesive ono the copper. This treatment is used to protect sheet copper E.g. slot in panels, And many examples of this coating have shown that this type of coating will ensure the life of your copper cladding will last 20+ years! No treatment, for 20+ years!

Coating additives need to be included in the treatment and protective layer of the copper cladding. Common additive are:

- UV absorbers – organic compounds which are sometimes added to coatings for exterior applications in order to prevent darkening and degradation of the coating. In some cases the /UV absorbers may interact with the substrate in the metal and prevent tarnishing. 2 benefits in 1!

- Levelling agents – These improve the flow properties of coatings and thereby provide a better surface coverage and overall appearance. The likelihood of dinholing and other defects is also reduced.

- Chelating agents – Benzotriazole and other chelating agents interact with the copper and its alloys that prevent tarnishing for years. It acts as an invisible barrier to elements or compounds that cause corrosion on the surface of the metal leading to a rusty and weathered appearance. It not only does that, but it protects the metal against oxidants that cause oxidation. This permeates through the initial coating and continues to protect even after a minor defect may form in the coating. Chelating agents may be included in the coating formulation or applied as part of a pre-treatment procedure.

In order for these treatments to perform to expectation the copper must first be free of dirt, oil, dust, old finishes and finger prints as these all cause detriment to the overall finish and longevity of the copper cladding. The treatment of the copper must also be done as quickly as possible after the decontamination in order to prevent recontamination. E.g. treat the metal in a low dust environment, handling the copper wearing white gloves, and applying tarnish inhibitors (chelating agents).

Steel wool should NEVER be used as it may contain chemicals that stain the copper. A suitable oiption for this would be powdered pumice stone, The pumice powder is mixed in a solution of 5% oxalic acid solution and rubbed onto the surface of the metal using a cloth. After the abrasion has been administered it must be wiped dry with a clean cloth and all residue removed from the surface.

Copper cladding is absolutely beautiful and has many benefits, being 100% recyclable is a huge bonus and means that your building is that little bit more green. It is shiny and reflects light brightening up all places and structures. It is easy to install, although not so easy to treat.

At Grey’s of London we are going to be thinking a great deal about how we can incorporate copper cladding into our designs and what benefits they will bring to us and our clients.